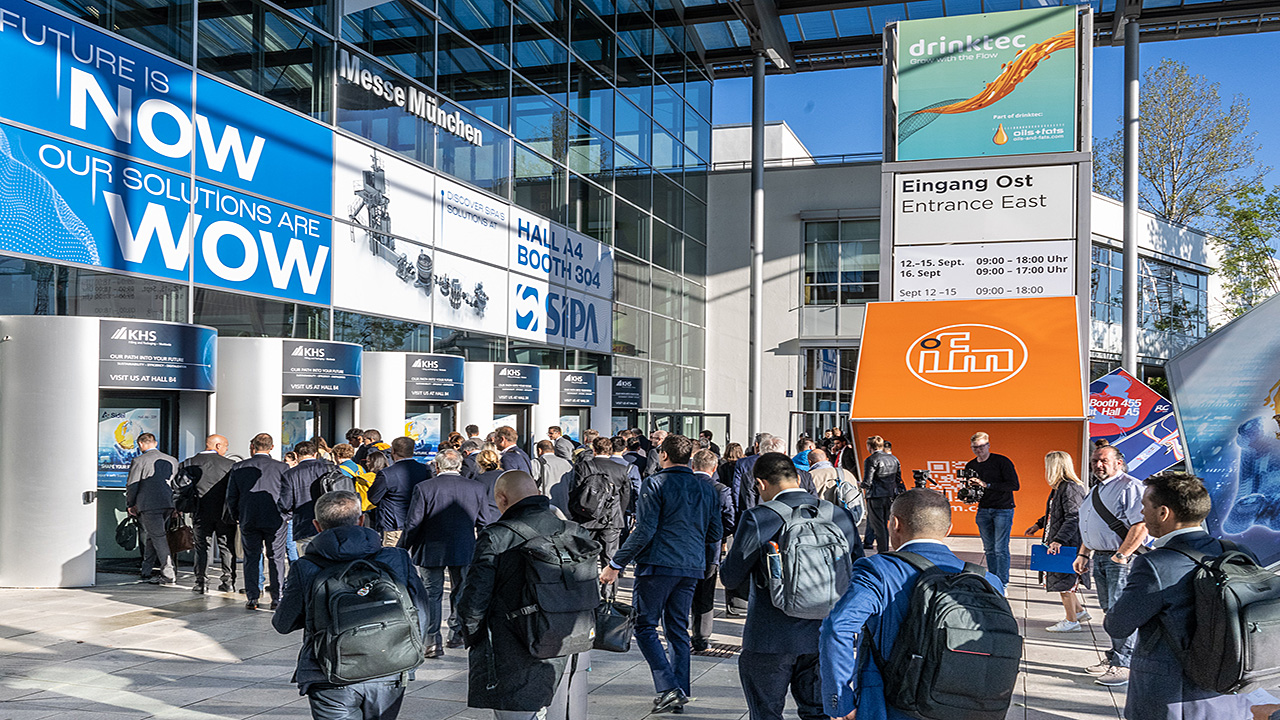

Two weeks ago, our Food & Beverage team visited Drinktec in Munich, one of Europe’s leading trade fairs for the beverage and liquid food industry. A wide range of trends, innovations and ideas were presented, but one topic consistently surfaced in conversations with both suppliers and clients: sustainability in primary packaging.

A common goal: reducing environmental impact

Whether it was through innovations in materials, lighter bottles or reusability models, the message was clear: the packaging industry is accelerating its efforts to lower environmental impact. That ambition takes many forms and there’s no one-size-fits-all answer. Here are four key strategies that emerged from our visit:

1. Switching materials: PET, Aluminium & Bag-in-Box

Material innovation continues to evolve. We saw growing interest in:

- Aluminium cans for beer and soft drinks, prized for their recyclability and light weight.

- Bag-in-box and PET bottles in wine packaging, offering efficient transport and reduced environmental impact.

For instance, in Nordic countries, PET bottles are becoming the new norm for wine, driven by tax incentives and circular targets.

Material shifts can help reduce both weight and emissions but they must align with regulatory, consumer and logistical requirements.

PET-bottling line for beverages

2. Lightweight glass bottles: doing more with less

Glass remains a preferred material in many sectors, but reducing the grammage (weight) of bottles is gaining traction. The goal is to maintain quality and product safety while reducing carbon emissions in production and transport.

Challenges persist:

- Thinner bottles may lead to higher breakage rates.

- Consumer perception of “light” may not always equal “premium”.

Still, suppliers are improving the durability of lightweight bottles, making this a promising route for many beverage producers.

3. Reusable packaging: closing the loop

Returnable glass bottles and jars remain a popular strategy to increase reusability of glass packaging. By investing in reverse logistics and cleaning infrastructure, packaging can be reused across multiple life cycles, significantly reducing waste.

At GAASCH PACKAGING, we actively support this circular model through our participation in BringBack, a circular innovation project focused on returnable glass bottles and jars in the Belgian market.

Crates of Glass Soda Bottles

4. Eco-design: rethinking packaging from the start

Another impactful strategy is to redesign packaging from the ground up, applying the principles of eco-design:

- Avoid over-packaging

- Reduce raw material use

- Optimise shape and size for efficient transport

- Minimise use of complex or multi-layer materials

Eco-design is not just about material selection; it’s about making smart choices at the concept stage. This leads to more efficient production, easier recycling, and a lower total environmental impact.

A tailored, independent approach

At GAASCH PACKAGING, we help producers across the food and beverage sector navigate these choices.

- We offer material-agnostic advice, looking at glass, plastic and alternatives based on your needs.

- We are supplier-independent, which means we recommend the solution that fits your specific product, production and sustainability objectives.

- We support your projects from idea to delivery, including design, compliance, forecasting, stock management and full-service follow-up.

Whether you’re looking to switch materials, redesign your bottle, or explore return models, we bring clarity and expertise to your packaging challenges.

Get in touch to discuss how we can support your shift to more sustainable packaging.